Durable Stainless Steel Tubes for Modern Architectural Designs

Benefits of Durable Stainless Steel Tubes in Architecture

Corrosion Resistance for Longevity

Stainless steel's innate resistance to rust and corrosion significantly extends the lifecycle of architectural elements, making them especially suitable for structures exposed to harsh environmental conditions. This material's durability is backed by research indicating its longevity can stretch up to 50 years or even longer in challenging environments, thereby considerably reducing the need for timely replacements. Beyond aesthetics, corrosion resistance is vital in enhancing the safety of buildings by minimizing the risk of material failure over time, ensuring robust and secure structures.

Structural Integrity Under High Stress

Durable stainless steel tubes are specifically engineered to withstand high loads and stresses, which makes them ideal for supporting critical architectural features like skyscrapers and bridges. Their superior tensile strength—approximately 50% greater than that of mild steel—provides an additional layer of safety and reliability, crucial for constructions in high-stress environments. The application of stainless steel in such demanding areas illustrates its exceptional capability to maintain structural integrity under extreme conditions.

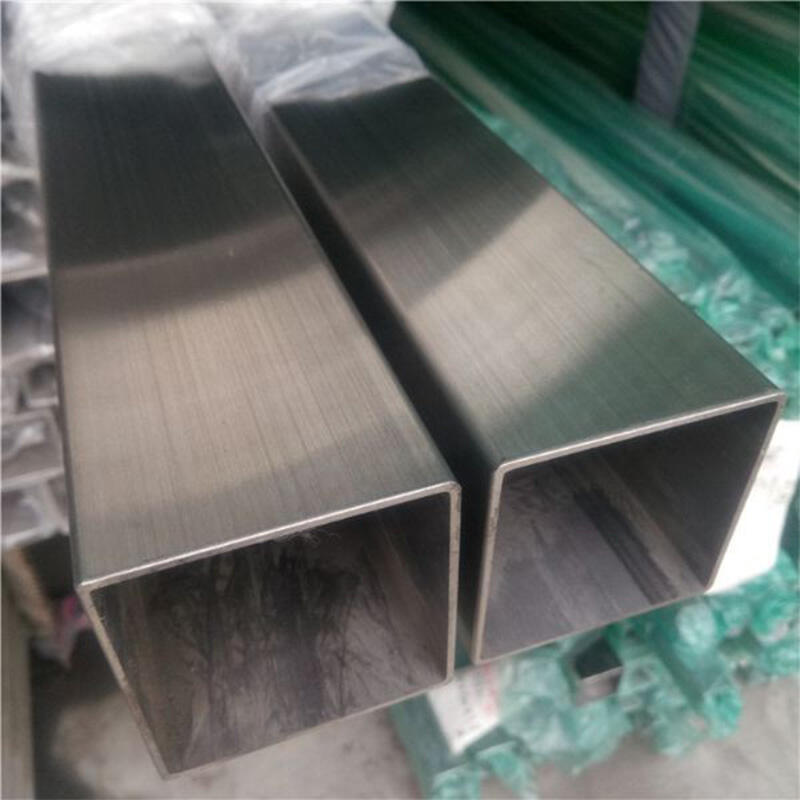

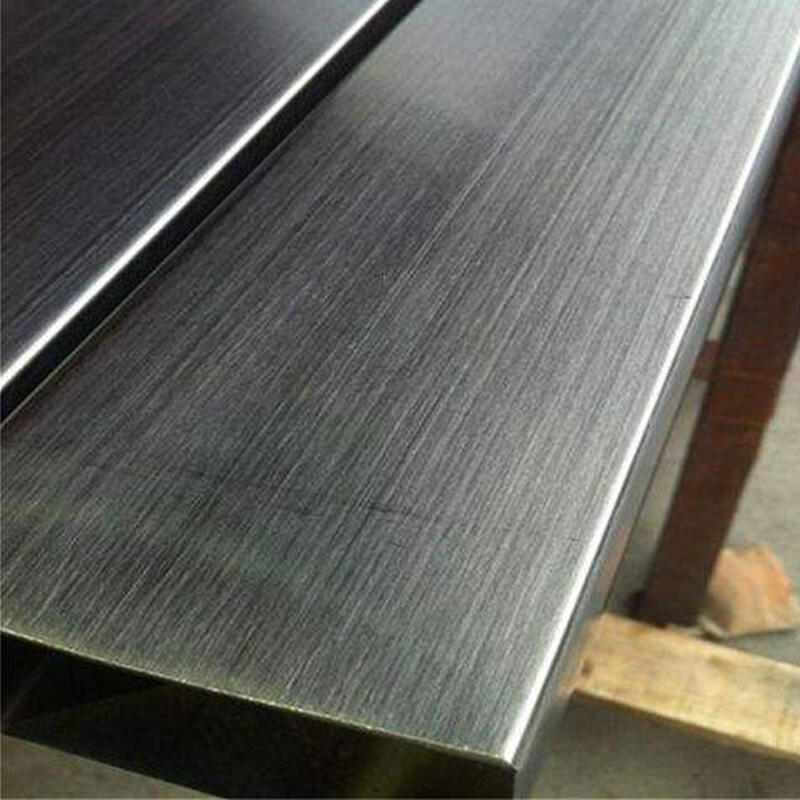

Aesthetic Versatility for Modern Designs

Stainless steel tubes offer great aesthetic versatility, allowing architects to achieve various modern design trends. They can be finished in numerous styles such as polished, brushed, or matte, and seamlessly integrate into diverse architectural styles. Plus, the reflective properties of stainless steel enhance the flow of natural light within spaces, creating visually appealing environments that are both functional and beautiful. This versatility makes stainless steel an excellent choice for contemporary architectural designs that prioritize vibrant and sophisticated aesthetics.

Applications of Stainless Steel Tubes in Modern Construction

Structural Frameworks and Support Systems

Stainless steel tubes are pivotal to the structural frameworks and support systems in modern construction. Due to their robust strength and light weight, they provide essential support for high-rise structures and complex architectural forms. This material reduces the overall weight of a building while maximizing its strength and stability, an ideal combination for skyscrapers and other large-scale constructions. For instance, case studies demonstrate that using stainless steel frameworks can increase energy efficiency due to reduced material use, contributing to sustainable building practices.

Decorative Elements in Façades and Interiors

In modern architecture, stainless steel tubes are extensively used for decorative elements in façades and interior designs. They lend unique texture and visual interest to building exteriors, often enhancing outdoor aesthetics significantly. Inside buildings, these tubes are used for railings, fixtures, and supports, adding elegance and modern flair to spaces. Their versatility allows designers to craft intricate designs that effectively combine form and function, transforming simple spaces into stylish environments.

HVAC and Fluid Transport Systems

In HVAC systems, stainless steel tubes are essential due to their ability to maintain temperatures and resist corrosion. Their durability ensures they remain reliable for plumbing infrastructure over time. These tubes are also commonly used for transporting fluids, thanks to their excellent high-pressure capabilities. This characteristic makes them suitable for various fluid transport applications, from industrial settings to residential plumbing, ensuring consistent performance and minimizing maintenance requirements.

Stainless steel tubes not only support structural integrity but also elevate aesthetic designs and offer operational reliability in transport systems. Their multifaceted use in modern construction showcases their indispensable role in achieving long-lasting durability, energy efficiency, and creative design solutions in architecture and engineering.

Material Grades: 201 vs. 304 vs. 316L Stainless Steel

201 Stainless Steel: Cost-Effective Durability

201 stainless steel provides a balance between usability and cost-effectiveness, making it a popular choice in general construction applications. Its corrosion resistance is quite good, especially in environments that aren't overly harsh, which helps to increase the lifespan of structures without significantly increasing project costs. For projects where cost is a significant consideration, while ensuring the structural integrity and reliability of the materials, 201 stainless steel becomes highly beneficial. This grade is particularly useful in applications where higher strength-to-weight ratios are necessary but environmental exposure is limited.

316L: Premium Corrosion Resistance for Harsh Environments

316L stainless steel is unparalleled in its corrosion resistance, making it ideal for use in harsh environments, such as marine and chemical processing applications. This steel grade maintains its strength and performance even at extremely high temperatures and under challenging conditions. The addition of molybdenum enhances its ability to resist pitting and localized corrosion, surpassing 304 stainless steel in performance in aggressive, corrosive settings. For industries that demand reliability in severe conditions, 316L stainless steel offers the peace of mind that structures and components will endure over time without compromising integrity.

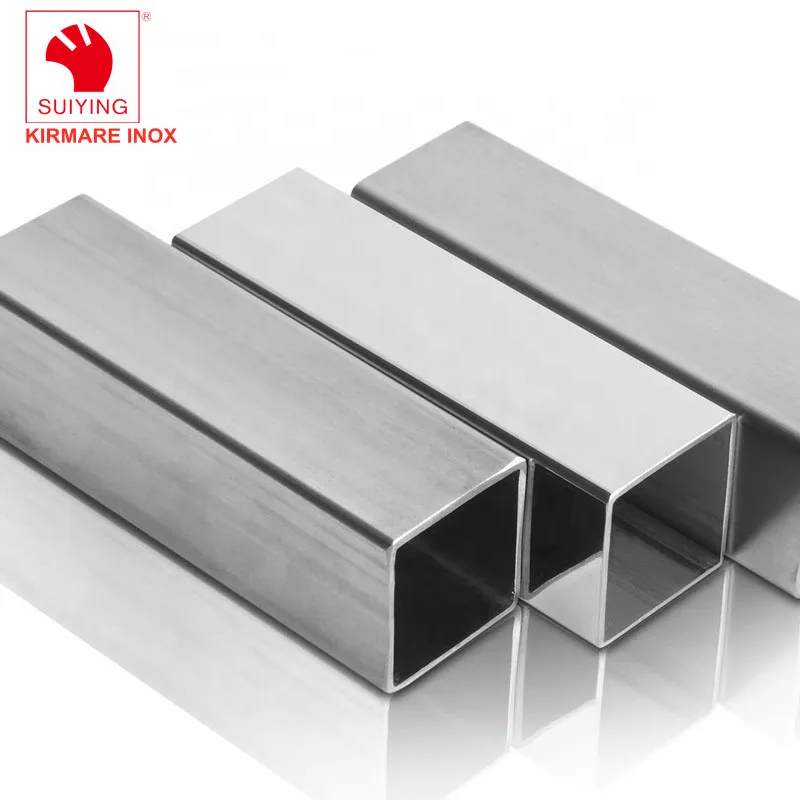

Top Stainless Steel Tube Products for Architectural Use

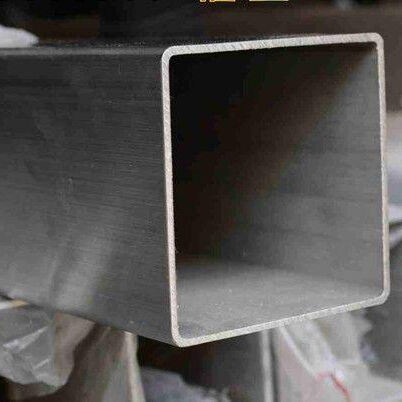

201 Stainless Steel Square Decorative Square Pipes

The 201 Stainless Steel Square Decorative Square Pipes are an outstanding choice in architectural design due to their aesthetic allure and robust structural characteristics. These pipes are often employed in modern architecture, where their sharp corners and impeccable finish contribute significantly to sleek and stylish designs. Available in a wide range of dimensions and finishes, they can be customized to meet specific design needs, ensuring they fit seamlessly into any architectural vision.

201 Mirror Polished Stainless Steel Square Tubing

201 Mirror Polished Stainless Steel Square Tubing adds a luxurious finish to architectural projects, reflecting surroundings with impeccable clarity. The mirror polish not only imbues surfaces with a high-end visual quality but also provides resistance against fingerprints and smudges, ensuring the tubing maintains its pristine appearance over time. This makes it particularly suitable for decorative applications in both interior and exterior settings, enhancing elegance wherever it's applied.

Hot-sale Stainless Steel Square Tubing 201

The Hot-sale Stainless Steel Square Tubing 201 is highly favored for its exquisite finish and robust nature, making it suitable for both residential and commercial projects. This popular variant often highlights trending styles and preferences in the market, providing valuable insights for architectural designs. Additionally, many suppliers offer bulk purchasing options, which is advantageous for larger endeavors seeking to leverage this tubing's strength and finish at scale.

Hot-sale Stainless Steel Rectangular Pipes Specifications 201

Hot-sale Stainless Steel Rectangular Pipes Specifications 201 are versatile, extensively utilized for both structural and decorative applications. They allow for broad customization due to varied specifications, accommodating unique architectural designs. These products typically adhere to strict quality standards, ensuring both aesthetic and structural integrity in architectural undertakings.

316L Stainless Steel Decorative Rectangular Pipes

316L Stainless Steel Decorative Rectangular Pipes excel in high-end architectural applications, especially in environments prone to corrosion. These pipes blend functionality with sophistication, making them suitable for facades and internal layouts. Their specifications are tailored to meet stringent architectural codes and standards, ensuring reliable performance alongside artistic appeal in projects where both elegance and durability are paramount.

Selecting the Right Stainless Steel Tube for Your Project

Matching Material to Environmental Demands

Evaluating environmental conditions is crucial in determining the appropriate stainless steel grade for your project. Different grades offer specific benefits in terms of corrosion resistance and strength, making it essential to select the right material based on the specific demands of the environment. For instance, projects in coastal areas may require higher-grade stainless steel that can withstand salty air and water exposure. Consulting with structural engineers can ensure that these choices align with the project specifications, guaranteeing both durability and functionality.

Customization Options for Unique Designs

Advancements in manufacturing have opened the door to extensive customization options for stainless steel tubes, allowing designers to create truly unique architectural pieces. By specifying dimensions, finishes, and grades, one can tailor stainless steel tubes to fit specific aesthetic and functional requirements. This customization enhances the overall aesthetic and functional attributes of a project, making it possible to integrate the tubes seamlessly into various design concepts. Opting for tailored solutions means that every detail in the design can contribute to the desired visual and structural outcomes, whether it's for modern facades with stainless steel square tubes or intricate architectural interiors.

EN

EN

AR

AR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

LT

LT

SR

SR

SL

SL

UK

UK

TH

TH

TR

TR

FA

FA

AF

AF

GA

GA

IS

IS

MK

MK

AZ

AZ

BN

BN

LO

LO

LA

LA

MN

MN

MY

MY

KK

KK

KY

KY